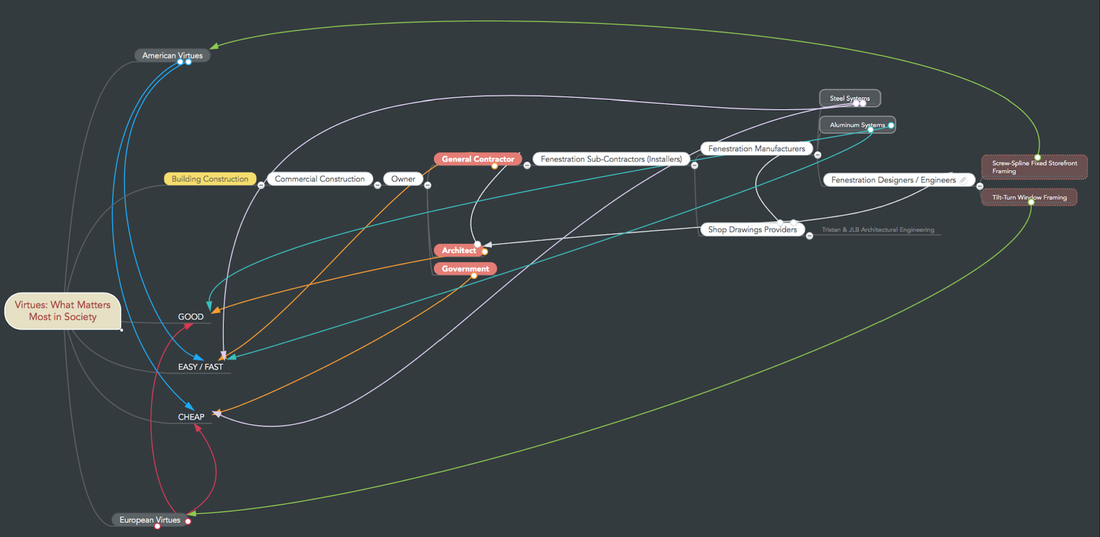

Virtues are aspects and ideas that are most important to a society, the valued qualities of a social structure. There are virtues that pertain to certain groups or countries. They make individual, small societies unique. No matter where one belongs in the world, the processes of building construction show the virtues their society holds tightly. What ideas and qualities are valued and what are forsaken in a society can be seen in every contribution to the creation of any building, no matter the size or purpose.

Building construction can be split into two main sections: residential and commercial. Residential work is always less intricate and developed versus commercial, which is understandable; commercial buildings and complexes are where we spend most of our time. They are where our work gets done.

Every part and contribution to the overall completed construction to a commercial building is equally important, but some are well overlooked. Fenestrations, arrangements of window or window-related products, are often recognized but without much attention. The industry for design, manufacturing and installing fenestration systems is relatively small and unpopular among the other trades of general building construction. The amount of detail that goes into what seems like a simple window is immense. It’s hard to see this from an inattentive outside view; to see and try to understand the amount of engineering that is done for fenestrations, the glass must be broken.

From a general or broad perspective of building construction as a whole, it’s rather difficult to make out a society’s virtues; but when the processes are broken down and individual trades are analyzed, conclusions are more easily in determining a society’s virtues. In this study, fenestrations hold these conclusions.

In the development of a product, the designers and engineers must choose two of three aspects that the product will have: “good”, “easy”, and “cheap”. A society exemplifies their virtues through these choices, through product design.

Most manufacturers and designers in the fenestration industry recognize several separate markets for the same types of products, and create based on trends in individual markets. The two largest markets are the US and Europe market. Though these societies are remarkably similar as a whole, in the fenestration industry, they are entirely different. Their unique virtues and demands resulted in their own markets. The products that are largely popular in the US are quite the opposite in Europe, and likewise, the popular products in Europe are often unheard of in the US.

The first metal fenestration systems were composed of steel. The industry was not nearly as large as it is today, partially due to modern globalization but mainly because steel systems had little variation between manufacturers. Designs were significantly fewer and simpler, consistent across the US and Europe as well. The rise of aluminum created a spur of growth and development in the fenestration industry. Steel systems were starting to be replaced by new aluminum systems in the 1960s. Even with little development in designs and poor performance compared to today’s frames, the first aluminum fenestrations outdid steel fenestrations by far; aluminum was lighter and more malleable, allowing easier manufacturing and installation. More complex shapes that couldn’t be done with steel were made possible with aluminum. The fenestration industry expanded in design throughout the 1970s and 1980s. As more manufacturers were founded and new design concepts emerged, what was once a more global market split into several markets, with designs pertaining to the geography of these markets; the US market holds different virtues than the Europe market, therefore the products in demand are also different between the two.

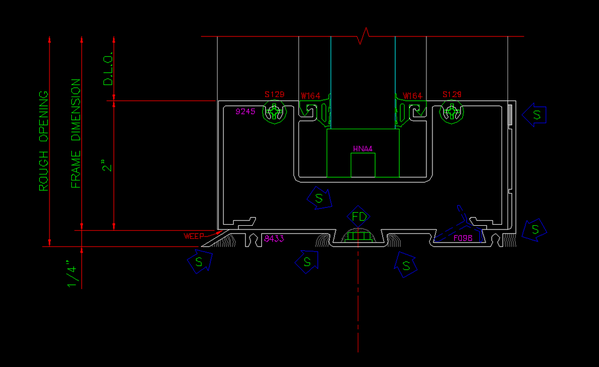

The most significant type of fenestration product used in the US is storefront framing. Shown below is a sill detail from EFCO Corporation, Series 402NT.

Building construction can be split into two main sections: residential and commercial. Residential work is always less intricate and developed versus commercial, which is understandable; commercial buildings and complexes are where we spend most of our time. They are where our work gets done.

Every part and contribution to the overall completed construction to a commercial building is equally important, but some are well overlooked. Fenestrations, arrangements of window or window-related products, are often recognized but without much attention. The industry for design, manufacturing and installing fenestration systems is relatively small and unpopular among the other trades of general building construction. The amount of detail that goes into what seems like a simple window is immense. It’s hard to see this from an inattentive outside view; to see and try to understand the amount of engineering that is done for fenestrations, the glass must be broken.

From a general or broad perspective of building construction as a whole, it’s rather difficult to make out a society’s virtues; but when the processes are broken down and individual trades are analyzed, conclusions are more easily in determining a society’s virtues. In this study, fenestrations hold these conclusions.

In the development of a product, the designers and engineers must choose two of three aspects that the product will have: “good”, “easy”, and “cheap”. A society exemplifies their virtues through these choices, through product design.

Most manufacturers and designers in the fenestration industry recognize several separate markets for the same types of products, and create based on trends in individual markets. The two largest markets are the US and Europe market. Though these societies are remarkably similar as a whole, in the fenestration industry, they are entirely different. Their unique virtues and demands resulted in their own markets. The products that are largely popular in the US are quite the opposite in Europe, and likewise, the popular products in Europe are often unheard of in the US.

The first metal fenestration systems were composed of steel. The industry was not nearly as large as it is today, partially due to modern globalization but mainly because steel systems had little variation between manufacturers. Designs were significantly fewer and simpler, consistent across the US and Europe as well. The rise of aluminum created a spur of growth and development in the fenestration industry. Steel systems were starting to be replaced by new aluminum systems in the 1960s. Even with little development in designs and poor performance compared to today’s frames, the first aluminum fenestrations outdid steel fenestrations by far; aluminum was lighter and more malleable, allowing easier manufacturing and installation. More complex shapes that couldn’t be done with steel were made possible with aluminum. The fenestration industry expanded in design throughout the 1970s and 1980s. As more manufacturers were founded and new design concepts emerged, what was once a more global market split into several markets, with designs pertaining to the geography of these markets; the US market holds different virtues than the Europe market, therefore the products in demand are also different between the two.

The most significant type of fenestration product used in the US is storefront framing. Shown below is a sill detail from EFCO Corporation, Series 402NT.

Storefronts meet the criteria of “easy” and “cheap”. They have simplistic designs, consisting of minimal parts and a uniform appearance. Storefront framing is always fixed, meaning there is no user operation, like a vent or hopper. Horizontal and vertical mullions are nearly identical, which reduces the cost per frame. Installation is done via the stick method in the field: assembling the mullions using screw spline ports or shear blocks and glazing in-place. This also saves money as most fenestrations are pre-assembled and glazed in the factory, then placed in their proper positions in the field. Shapes and sizes are fairly consistent across manufacturers. The typical size is 2” (sightline) X 4-1/2” (depth). The commodity of the shapes and sizes and simple designs make storefronts easy to manufacture and install while also being inexpensive. However, as a result of all these aspects, storefront thermal performance is very poor and there are no options for operable frames. From these details of the most popular US frame type, it can be concluded that “easy” and “cheap” are virtuous to American people.

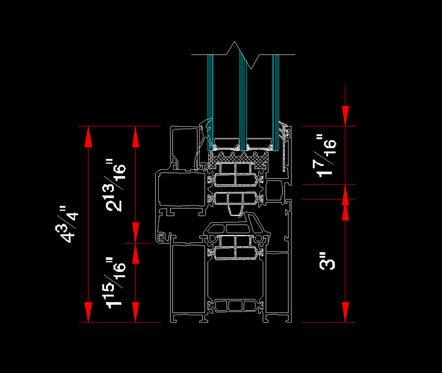

The most significant type of fenestration product used in Europe is tilt-turn window framing. Shown below is a sill detail from Glo European Windows, Series A5.

Tilt-turn windows are almost unique to European countries and meet the criteria of “good” and “easy”. They have complicated designs, consisting of many parts and lack a uniform appearance. Tilt-turn windows, as implied by the name, have the function to act as an awning (project-out) and open like a door as well. Horizontal and vertical mullions are drastically different, which increases the cost per frame and time to manufacture. Installation is easily done via pre-assembly and glazing in the factory, then placement in their proper positions in the field. This also increases cost and makes it so there is no room for accuracy error; measurement precision becomes more important and much more effort is put into shop drawings and pre-installation field measurement. Shapes and sizes are hardly consistent across manufacturers. There aren’t typical overall sizes for windows as different manufacturers have very different designs for the same type of product. Regardless of the manufacturer, tilt-turn windows are excellent in thermal performance because of the complicated and functional designs. European-style triple-pane glazing also increases thermal performance. From these details of the most popular European frame type, it can be concluded that “good” and “easy” are virtuous to European people.

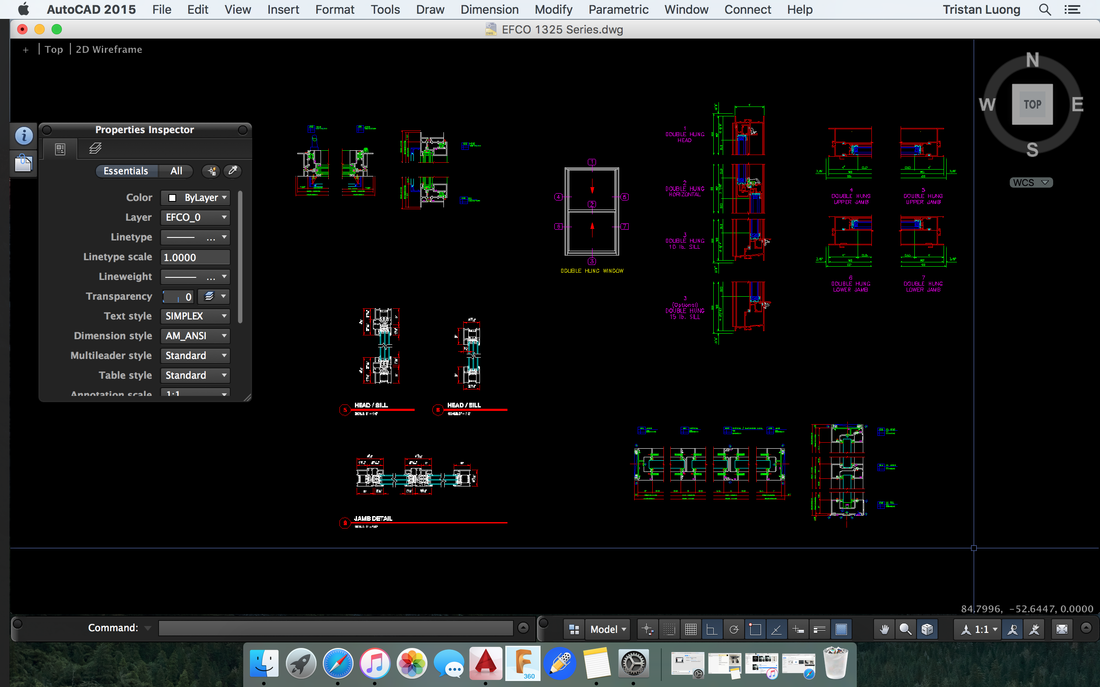

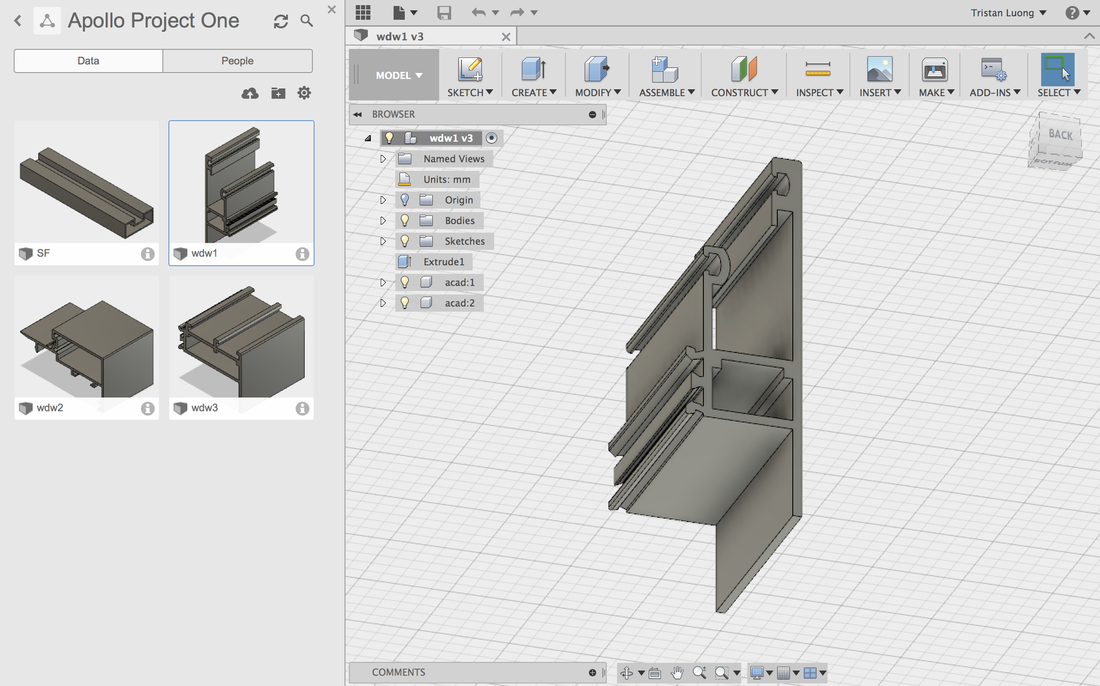

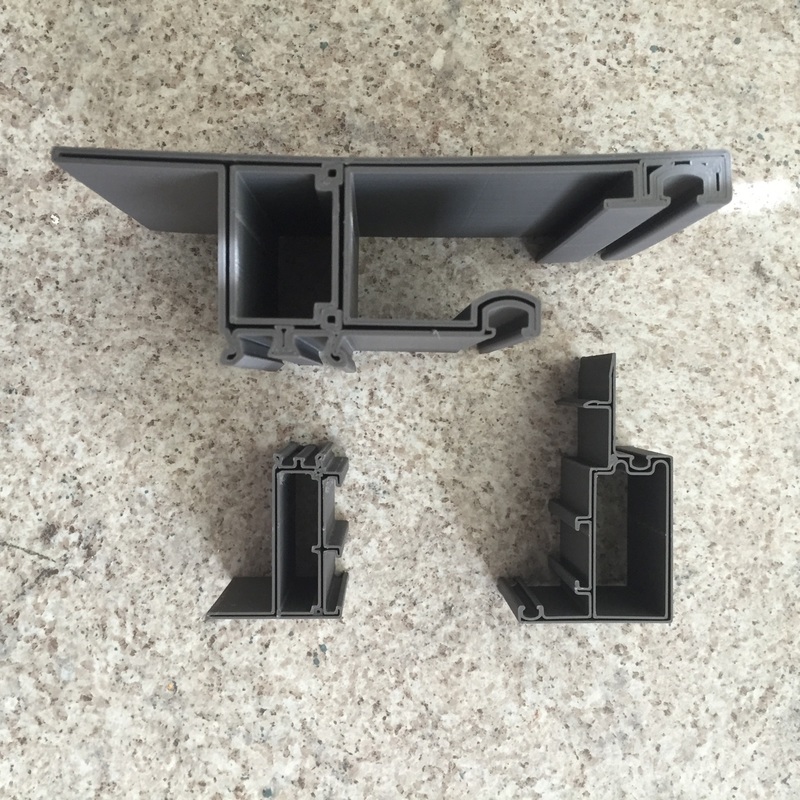

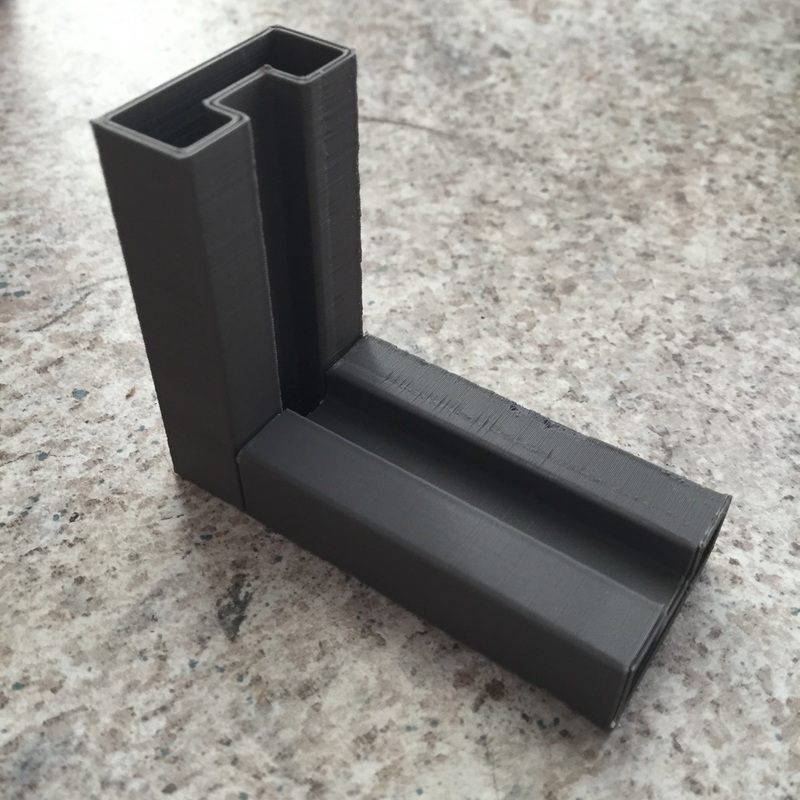

Through the images below, the process of 3-D printing some of the mentioned mullions is explained.